Guest post: Reducing material use could cut emissions from cars and homes by at least a third

Multiple Authors

06.08.22Multiple Authors

08.06.2022 | 1:34pmProducing the steel, concrete and other materials that go into our cars and homes accounts for a quarter of all greenhouse gases, so using these things more efficiently has significant potential for emissions cuts.

In our recent study, published in Nature Communications, we found that constructing lighter and smaller products, combined with more intense material use and some behavioural shifts, could cut emissions from these sectors by between one and two thirds.

What is more, making these changes does not require any technological breakthroughs – just willingness among politicians and citizens.

We investigated the production, use and disposal of residential buildings and vehicles in the period up to 2050, exploring different assumptions about demand, population size and climate policies.

Our modelling shows how material efficiency can deliver savings on top of energy efficiency and low-carbon energy supply, making it the third pillar of deep decarbonisation for these sectors.

Different futures

The construction sector is responsible for 40% of material-related carbon dioxide (CO2) emissions. We chose to focus on residential buildings because they are the largest energy and material consumers in this sector.

We found that reducing the amount of materials used in house construction, known as “dematerialisation”, could cut emissions by a cumulative total of 20-50bn tonnes of CO2 equivalent (GtCO2e) by 2050.

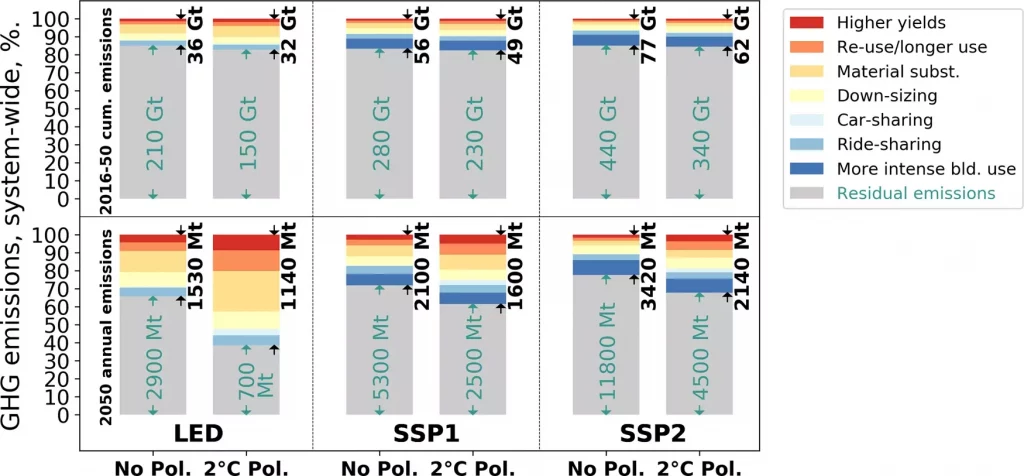

The cumulative impact of such strategies over the coming decades can be seen in the red, orange and yellow sections of the top row of charts below, under three different future scenarios – Low Energy Demand, Shared Socioeconomic Pathway 1 (SSP1) and SSP2.

The outcome of material efficiency strategies also depend on future climate policies. We compared scenarios in which more clean energy and electric cars keep warming within the 2C goal of the Paris Agreement, to those without additional climate policies beyond what is already in place. These alternatives are marked “2C Pol” and “No Pol” in the chart below.

The blue sections of the chart show the impacts of material efficiency interventions in the manufacturing sector, which accounts for another 40% of material-related CO2 emissions. Passenger vehicles account for most of the consumption in this sector and we found that emissions related to cars could be reduced by a cumulative total of 13-26GtCO2e during the same period out to 2050.

Sharing and downsizing

Overall, we looked at 10 different strategies to reduce materials use and emissions, assuming that such approaches would be in place by 2040.

If this is the case, our results showed that by 2050, the annual emissions related to homes and cars would be reduced by roughly between one- and two-thirds, compared to emissions without the implementation of these strategies.

Three strategies for material efficiency on the demand side can provide most of the reductions from vehicles.

These include ride sharing or carpooling, which reduces both car numbers and distances driven by riding together, and can be facilitated by apps such as BlaBlaCar and Scoop. Similarly, car sharing – meaning people rent nearby cars on a short-term basis – can be effective in reducing car ownership.

The third measure for vehicles is reducing the size, and therefore weight, of cars. This may happen automatically as a result of car sharing, as rental cars can be trip-appropriate compared to purchased cars, which must be all-purpose.

For homes, demand-side material efficiency is key. Here, we assumed that floor space per capita could be cut by up to 20% compared to the baseline, reducing the amount of building material needed as well as the energy required to heat or cool the building.

One measure to reduce floor space is if people live in multi-unit dwellings instead of single-family houses, which would also increase urban density and could incentivise public transport over driving.

We also investigated the use of timber instead of concrete and masonry, which has much lower emissions and sequesters carbon. Our model assumed only a limited supply of wood, but we found that total demand did not increase if we combined wooden buildings with floor space limits.

We also considered increased recycling, reuse of parts, longer product lifetimes, larger yields from production processes and the construction of lighter products. All these strategies offered material savings, but emissions reductions were only modest.

There is already a substantial degree of metal recycling, which saves a lot of emissions, but expanding recycling to other materials has fewer benefits than the recycling that already occurs.

We also found that product lifetime extensions benefited the climate only when they were applied to efficient buildings and electric vehicles, not to poorer-performing products in the current stock.

More than recycling

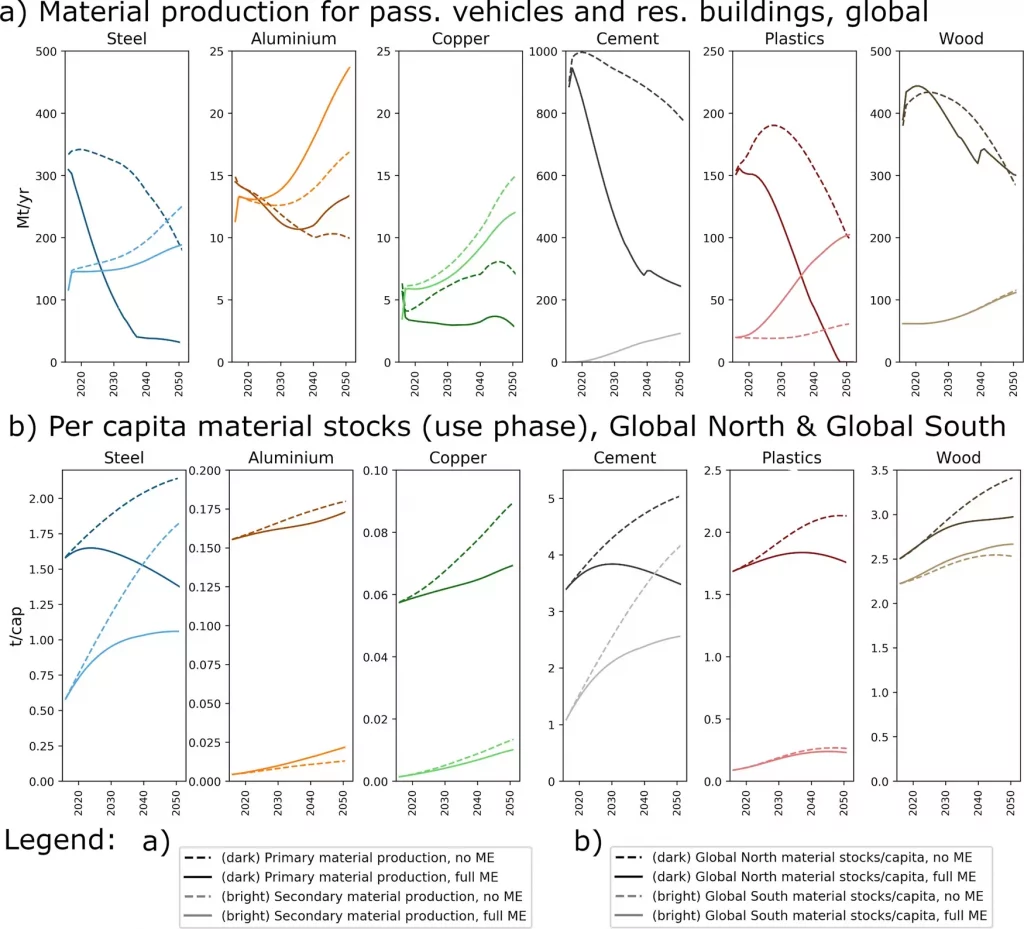

Overall, the strategies we investigated would substantially reduce the demand from these two sectors for the “primary” materials produced from natural resources.

Primary steel demand would drop to a sixth, cement demand to a quarter and copper demand would halve, compared with the levels needed without material efficiency interventions (dark solid versus dark dashed lines in the chart, respectively).

These materials would largely be replaced by recycled – or “secondary” – materials, something that can be seen in the chart below (bright lines).

For those promoting the circular economy, this would be a significant development. However, we also showed that cutting overall demand for new products and therefore materials is at least as important as increasing recycling, especially for establishing co-benefits between circular economy and climate change mitigation.

For this research, we built a new model that traces product vintages, their composition and operational characteristics from production through use and maintenance, and ultimately to the end-of-life where the materials become available for recycling.

This model was first applied to the G7 countries in a report for the International Resource Panel, which has informed the formation of the EU’s Circular Economy Action Plan and its Renovation Wave.

The research also shows that, in absolute terms, emissions cuts from dematerialisation in developing countries are much larger than those in industrialised countries. Realising some of these gains is perhaps not trivial in terms of policy innovations, but it requires no technical breakthroughs. In fact, the technologies are all in place and we could begin making the gains identified by our research almost at once.

Pauliuk, S. et al. (2021) Global scenarios of resource and emission savings from material efficiency in residential buildings and cars, Nature Communications, doi: 10.1038/s41467-021-25300-4